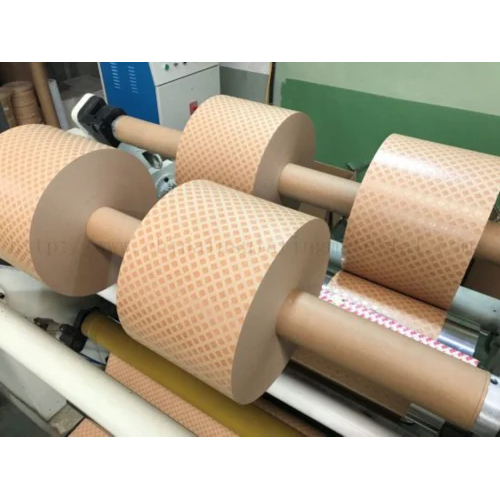

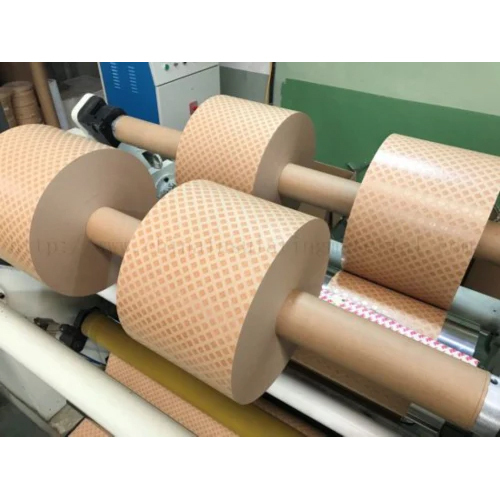

Epoxy Diamond Dotted Paper for Transformers Industry

Epoxy Diamond Dotted Paper for Transformers Industry Specification

- Length

- 100 m Meter (m)

- Operating Temperature

- -10C to 130C Celsius (oC)

- Elongation

- 3%

- Width

- 1000 mm Millimeter (mm)

- Thickness

- 0.08 mm, 0.13 mm, 0.18 mm (Available Range: 0.08 ~ 0.25 mm) Millimeter (mm)

- Density

- 0.98 Gram per cubic centimeter(g/cm3)

- Thermal Conductivity

- 0.25 W/mK Watt/Meter/K (w/(m.k)

- Shelf Life

- 12 Months (Store below 25C, dry conditions) Months

- Product Type

- Insulation Paper

- Application

- Dry Type , Oil Cooled Transformers

- Material

- Electrical Insulating Paper with Epoxy Resin Dotted Coating

- Rated Voltage

- 3.6 kV Volt (V)

- Tensile Strength

- 70 N/10mm Newtons per Millimetre Squared (N/mm2)

- Function

- Electrical Insulation & Interlayer Bonding

- Heat Resistance

- Class B (130C)

- Paper Core

- 76 mm (3-inch)

- Color

- Brown

- Weight

- Approx. 90 - 125 g/m (depending on thickness) GSM (gm/2)

- Adhesion Strength

- 2 N/cm

- Environmental Resistance

- Good resistance to transformer oil and humidity

- Roll Inner Diameter

- 76 mm

- Packaging

- Wrapped & Carton Packed

- Resin Content

- 18% 2%

- Diamond Pattern Distance

- 8 mm

- Cutting Tolerance

- 1 mm

- Odor

- Odorless

- Curing Temperature

- 90C 110C

- Flame Retardancy

- Self-extinguishing

- Curing Time

- 30 minutes

- Surface Finish

- Semi-gloss

- Moisture Content

- 7%

Epoxy Diamond Dotted Paper for Transformers Industry Trade Information

- Minimum Order Quantity

- 120 Kilograms

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- 7 Days

About Epoxy Diamond Dotted Paper for Transformers Industry

Discover Crackerjack savings with our hot-selling Epoxy Diamond Dotted Paper, engineered for the transformer industry. Offering radiant, lavish performance at an affordable rate, this electrical insulating paper features an epoxy resin dotted coating (18 2) and a diamond pattern (8 mm spacing) for superior adhesion (2 N/cm) and interlayer bonding. Benefit from excellent thermal conductivity (0.25 W/mK), self-extinguishing flame retardancy, and robust resistance to transformer oil and humidity. Available in brown, odorless rolls (width: 1000 mm, length: 100 m, thickness range: 0.080.25 mm), it complies with IEC 60641-3-1 standardsideal for both dry type and oil cooled transformers.

Application and Usage of Epoxy Diamond Dotted Paper

Epoxy Diamond Dotted Paper is expertly applied between layers of windings in dry type or oil cooled transformers, ensuring reliable electrical insulation and interlayer bonding. The semi-gloss surface finish allows easy handling and uniform layering on transformer cores. Install by cutting to required size and curing at 90C 110C for 30 minutes to activate the resin dots. Radiant surface adhesion and dimensional stability make it the preferred choice for transformer manufacturer and service provider in India.

Certifications and Export Details

Compliant with IEC 60641-3-1, our Epoxy Diamond Dotted Paper meets rigorous industry standards. Certifications guarantee quality and safety for transformer applications. With an FOB port located in India, we provide prompt shipping services to global export markets. Samples are available for testing and evaluation before bulk orders. Request a quotation for your project and benefit from competitive rates as a trusted supplier, distributor, and manufacturer of electrical insulation materials.

Application and Usage of Epoxy Diamond Dotted Paper

Epoxy Diamond Dotted Paper is expertly applied between layers of windings in dry type or oil cooled transformers, ensuring reliable electrical insulation and interlayer bonding. The semi-gloss surface finish allows easy handling and uniform layering on transformer cores. Install by cutting to required size and curing at 90C 110C for 30 minutes to activate the resin dots. Radiant surface adhesion and dimensional stability make it the preferred choice for transformer manufacturer and service provider in India.

Certifications and Export Details

Compliant with IEC 60641-3-1, our Epoxy Diamond Dotted Paper meets rigorous industry standards. Certifications guarantee quality and safety for transformer applications. With an FOB port located in India, we provide prompt shipping services to global export markets. Samples are available for testing and evaluation before bulk orders. Request a quotation for your project and benefit from competitive rates as a trusted supplier, distributor, and manufacturer of electrical insulation materials.

FAQs of Epoxy Diamond Dotted Paper for Transformers Industry:

Q: How is Epoxy Diamond Dotted Paper used in transformer manufacturing?

A: Epoxy Diamond Dotted Paper is placed between transformer windings to provide effective electrical insulation and interlayer bonding. The resin dots activate during curing, ensuring secure adhesion and insulation within both dry type and oil cooled transformers.Q: What are the benefits of using this paper in transformer applications?

A: This insulation paper offers excellent adhesion, self-extinguishing flame retardancy, radiant thermal conductivity, and robust resistance against transformer oil and humidity, promoting long-lasting, reliable performance in harsh transformer environments.Q: Where can the Epoxy Diamond Dotted Paper be applied?

A: It is suitable for dry type and oil cooled transformers, and can be applied on surfaces requiring electrical insulation between windings or layers in transformer cores.Q: When should the curing process be performed?

A: The curing process should be performed during or after installation, at temperatures between 90C 110C for approximately 30 minutes to ensure proper activation of the resin dots and secure adhesion.Q: What certifications does this product meet?

A: Epoxy Diamond Dotted Paper is manufactured in compliance with IEC 60641-3-1, confirming adherence to international quality and safety standards for transformer insulation materials.Q: How can I get a quotation or sample for export markets?

A: To receive a quotation or sample, contact us directly. We provide competitive rates, export services through Indias FOB port, and samples for evaluation prior to bulk orders.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Diamond Dotted Paper Category

Epoxy Diamond Dotted Paper

Price 195 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Product Type : Other, Diamond Dotted Paper

Shelf Life : 612 Months

Material : Other

Heat Resistance : 1

Send Inquiry

Send Inquiry Send SMS

Send SMS